Expertise in a wide range of filtering difficulties, as well as the improvement of existing systems

Faure Equipements supports you with your filtration tests, whether to design a new treatment unit or to improve an existing workshop, in our laboratory or directly on site using our pilot units.

FILTRATION TESTS

State-of-the-art equipment

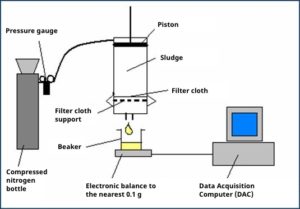

Our laboratory has the necessary equipment to analyze sludge and dewatered products (Jar-Test, measurement of CST, TSS, dryness, etc.). A compressibility cell that meets the NFT 97-001 standard and is fitted with a computerized acquisition system is one of our most notable assets.

It enables the determination of the dehydration stages’ distinctive parameters (limit dryness, compressibility, specific resistance). We designed a laboratory pilot that allows us to conduct tests on a limited product quantity and obtain relevant dehydration findings from a filter press (filtration time, dryness and density of the cake).

Several test platforms, as well as conditioning skids, are available for conducting industrial scale testing. They are easily transportable both in France and overseas and are fitted with cutting-edge technology (membrane trays, automated de-oiling).

TESTING PERFORMANCE

The laboratory pilot

Testing is now considerably more efficient thanks to the laboratory pilot.

The following parameters are confirmed for standard dehydration:

The following parameters are validated for process development

This department is managed by Christophe JAMMES,

in charge of Filtration Processes