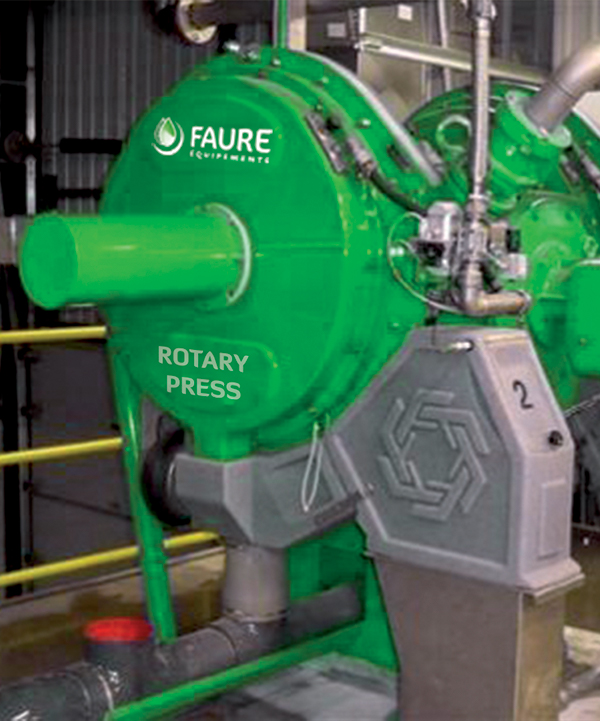

Rotary Press is an innovative piece of equipment developed in partnership with Fournier Industries in Canada

BENEFITS

Dehydration & liquid/solid separation with Rotary Press

Expandable

Sturdy and reliable

24-hour continuous process

Fully automated

Reduced space requirement

Low energy consumption

Low rotation speed

Self-cleaning 5mn a day

Non-mandatory thickening

Low maintenance

ROTARY PRESS

Operating principles

The sludge is fed at very low pressure into a space between two parallel filter elements.

As the free water drains from the slurry, the accumulated solids in the channel build up pressure against the outlet valve.

The slow rotation of the filter elements drags the solids by friction, generating enough pressure in the channel to allow the cake to extrude.

Optimum security

Have you got any questions?

Our technical sales team is here to help you!

Rotary Press

Applications

URBAN SLUDGE

Biological

Mixed

Digested

Septic tanks

Mixed

Digested

Septic tanks

INDUSTRIAL SLUDGE

Paper mill

Brewery

Slurry

Food industry

Plastic recycling

Tannery / leather industry

Brewery

Slurry

Food industry

Plastic recycling

Tannery / leather industry

FULL-SCALE PILOT UNITS

Laboratory and pilot tests possible